Common Applications for Industrial Vibrators:

Useful in a range of manufacturing, processing, OEM applications including:

- Bin, hopper & silo evacuation

- Chute & downcomer pipe vibrating

- Filter cleaning

- Consolidating/compacting

- Feeding

- Screening

- Shaking/cleaning

- Orienting & positioning

- Settling/jogging

- Conveying

- Fatigue testing

- Vibration during welding

- Dewatering/draining

- Product sizing

- Stress relief of castings & weldments

Industries that Include:

- Aggregate

- Cement

- Chemical

- Concrete Construction

- Feed and Grain

- Food Processing

- Foundries

- Manufacturing

- Mining

- Pharmaceuticals

- Plastics

- Power Generation

- Precast Concrete

- Public Utilities

- Pulp and Paper

- Railcar Unloading

- Truck Unloading

- Steel

- Waste Handling

- Water Filtration

Problems Solved with Flow Aids from AIRMATIC

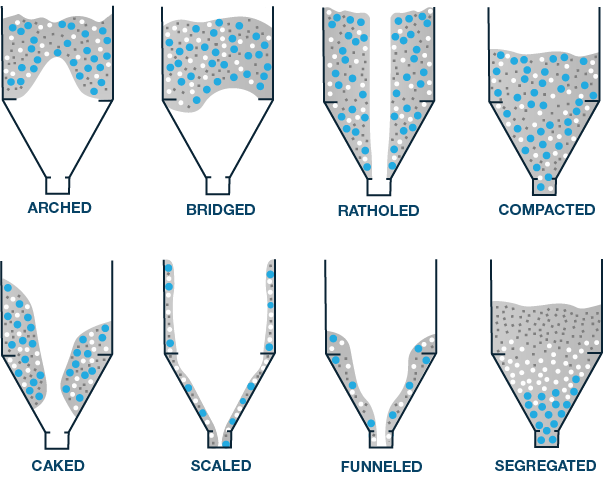

In bulk material handling, issues like funneling, ratholing, plugging, doming/arching, bridging, caking, and scale build-up often occur in bins, hoppers, and silos. These flow problems can disrupt operations, reduce efficiency, and lead to costly downtime. The selection of flow aid equipment, such as rotary or linear vibrators, air cannons, bin aerators, or sonic horns, depends on the characteristics of the bulk material and the type of flow obstruction.

Rotary and linear vibrators are ideal for materials prone to bridging or ratholing, where internal friction and cohesive forces cause obstructions. Vibrators induce mechanical agitation, breaking these blockages by shaking the structure and material, facilitating consistent flow.

Air cannons work by blasting powerful bursts of compressed air into the bin or silo, dislodging material buildup and preventing plugging and doming/arching in difficult-to-reach areas. This method is particularly effective for sticky, moist, or fibrous materials.

Bin aerators are suitable for fine, dry powders that tend to compact and cause caking or bridging. These devices introduce low-pressure air into the bulk material to aerate it, reducing material compaction and promoting smooth discharge.

Sonic horns utilize low-frequency sound waves to vibrate the walls of the structure, loosening materials like dust or fine particles, addressing caking and scale build-up.

By matching the appropriate equipment to the specific flow problem, facilities can maintain uninterrupted material flow and ensure operational efficiency.

Why Airmatic?

Industrial vibrators play important roles in numerous sectors of industry— manufacturing, concrete construction, mining, food processing, recycling, and much more. Since we also have long played a role in all these industries, we know industrial vibrators well. Count on us for the critical insight and knowledge that can help you make the right decisions on industrial vibrators for your operation.

Learn more reasons to buy from AIRMATIC.